Key features and advantages of aluminum motorcycle wheel hubs

2024-03-13

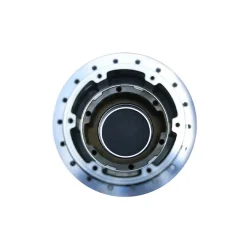

An aluminum motorcycle wheel hub is a crucial component in the motorcycle's wheel assembly. The wheel hub is the central part of the wheel that connects to the motorcycle's axle and supports the wheel's spokes or rim. Aluminum is a popular material for manufacturing motorcycle wheel hubs due to its lightweight nature, corrosion resistance, and strength-to-weight ratio.

Key features and advantages of aluminum motorcycle wheel hubs:

1. Lightweight: Aluminum is known for its low density, making it an ideal choice for motorcycle components where weight is a critical factor. A lighter wheel hub contributes to overall weight reduction, enhancing the motorcycle's performance, agility, and fuel efficiency.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer on its surface, which helps prevent corrosion. This is especially important for motorcycle wheels, as they are exposed to various weather conditions and road elements.

3. Strength: Despite being lightweight, aluminum offers good strength and durability. This allows the wheel hub to withstand the dynamic loads and stresses encountered during riding.

4. Aesthetic Appeal: Aluminum can be easily machined and shaped, allowing manufacturers to create aesthetically pleasing and intricate designs for motorcycle wheel hubs. This contributes to the overall visual appeal of the motorcycle.

5. Heat Dissipation: Aluminum has excellent heat dissipation properties, which is beneficial for components that may generate heat during operation. In a motorcycle, the wheel hub can benefit from this property, especially in high-performance or heavy-duty applications.

6. Ease of Manufacturing: Aluminum is a malleable and easily formable material, making it cost-effective and efficient to manufacture into complex shapes. This ease of manufacturing contributes to cost savings and allows for innovative designs.

It's important to note that while aluminum is widely used for motorcycle wheel hubs, different motorcycles may have variations in design and materials based on factors such as intended use, performance requirements, and manufacturer preferences. Additionally, advancements in materials and manufacturing processes may lead to the use of alternative materials or alloys in the future.